In this article, you will learn 12 different types of patterns in the casting process as well as their uses.

Pattern is very necessary for the casting process, without pattern we cannot make the product in casting.

In simple words, a pattern is a replica i.e. an object that looks similar to the final object.

A pattern is used to make a cavity in which molten metal or material is molded.

We can make patterns from different materials like wood, metal, plastic, and more.

Sometimes we also make patterns from wax and plaster of paris according to our needs.

So without wasting time let's get started.

What is a Pattern?

A pattern in a casting process, it is a replica of the object to cast and used to prepare the mold cavity into molten material poured during the casting process.

The sand casting pattern makes it the same shape as the part, not exactly the same size.

Because of the shrinkage provided when it is converted from liquid form into solid-state.

The common pattern materials from which patterns are made are wood, metal, plaster, plastic, wax, etc.

Mostly woods are used for making a pattern in the casting process.

Function of Pattern

- The proper design pattern is made with a smooth surface and reduces casting defects.

- Gates, risers, and runners are used in feeding molten metal in the cavity from a part of the pattern.

- The pattern contains a projection known as a core print if casting requires a core made of hollow parts.

- The pattern forms a mold cavity for making a casting.

Types of Pattern

- Match plate pattern

- Solid or Single Piece Pattern

- Split Pattern or Two-Piece Pattern

- Cope and Drag Pattern

- Shell Pattern

- Gated Pattern

- Sweep Pattern

- Loose Piece Pattern

- Segmental Pattern

- Skeleton Pattern

- Multi-Piece Pattern

- Follow Board Pattern

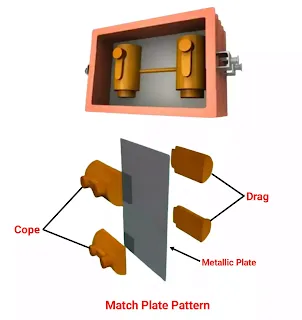

Match Plate Pattern

Basically, the match plate pattern is a split pattern but in the match plate pattern, the areas of cope and drag are on opposite faces of the metallic plate.

This metallic plate is called a match plate.

This type of pattern requires very little effort and gives very high output. Because the gate and the runner are also used on the match plate.

The match plate pattern is widely used for molding multiple products into a single molding box.

Solid or Single Piece Pattern

Solid type patterns are the simplest method for simple shape casting.

This pattern can be made in the mold without any sub-parts or joints.

In this type of pattern only simple shapes are produced and can be very easily removed from the mold.

The solid pattern is placed in drag. It is used to make a flat surface like gear blanks, square blocks, etc.

This type of pattern molding process is quite inconvenient and time-consuming. Therefore, such patterns are used to make some large castings.

Split Pattern or Two-Piece Pattern

The pattern is split into two half parts. One part of the pattern is in the drag and the other part is in the cope.

Split patterns are used to manufacture intricately shaped parts and large casting products.

It has two dowel pins and two dowel holes which are used to join and align the two pieces together.

Cope and Drag Pattern

The cope and drag type pattern is made in two parts, which are molded into separate molding boxes.

The mold cavity is prepared after the molding process is completed.

This is a different version of the split pattern as both are molded separately in the assembly position.

These types of patterns are used for casting heavy products.

Shell Pattern

The shell pattern is used to make molds of curved or straight hollow-shaped parts, such as pipes.

In this, the pattern is made of metal. The pattern is divided along the center line and the two halves are joined.

In this type of pattern, the outer shapes are used to make the mold and the inner shapes are used to make the core.

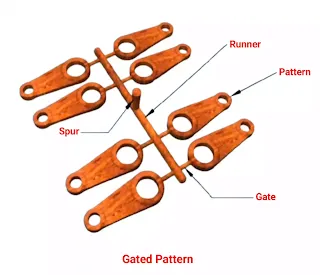

Gated Patterns

Gated type patterns are used to create multiple parts inside a single mould.

A gated pattern is nothing but a pattern consisting of one or more patterns.

Gates are used to connecting different patterns. These are loose patterns where gates and runners are already attached.

Sweep pattern

The sweep pattern is used to create large symmetrical molds by rotating the sweep attached to the spindle.

The sweep pattern consists of three parts spindle, base, and sweep which is a wooden board.

The spindle is directed in the vertical direction and is connected with the base sand. The plane is rotated 360°on an axis called symmetry or sweep.

The sweep pattern is used to produce large uniform molds with a circular cross-section.

Loose Piece Pattern

In a single piece pattern, a loose piece is created so that the pattern can be easily removed from the mold after the molding process is completed and a separate mold can be created.

This loose piece pattern is a highly efficient job and is also expensive.

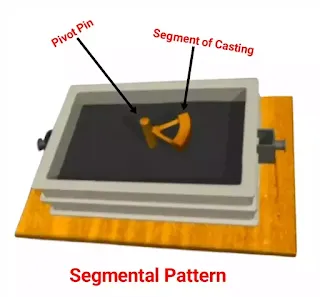

Segmental Pattern

A segmental pattern is used for making molds of large circular castings avoiding the use of solid patterns of the exact size.

It is similar to the sweep pattern, but differs from the sweep pattern, in that the sweep pattern of a part is the full rotational motion of the mold preparation.

Whereas the segmental pattern is not a complete rotational motion.

After ramming one section, the segmental pattern moves on to the next section. This process is repeated until the entire mould is completed.

Skeleton Pattern

In a small number of large castings, it is not economical to use solid patterns. In such cases, skeleton patterns are preferred.

This type of pattern consists of wooden frames and strips. This is called the skeleton pattern.

The mold is filled properly. Surplus sand is removed by means of a simultaneous sticker. The Skeleton pattern is used for castings that have a simple shape.

These castings are usually large in size.

For round shapes, these patterns are made in two halves and joined with glue or via screws.

Multi-Piece Pattern

This pattern is divided into three parts. The top part is called the coop, the bottom part is called the drag and the middle part is called the check.

All three parts are attached with dowel pins and clamps to the molding box.

Follow Board Pattern

The follow board pattern uses a wooden board as a base for the molding process.

This pattern is used in processes where casting structures are weak and may break after the application of force.

So, I hope I've covered everything about the "types of pattern in casting". If you still have any doubts or questions about the types of patterns, you can mail me or ask via comments, I will definitely reply to you as soon as possible.

If you liked this article then you can share it with your friends and spread the knowledge.

Thank You.

1 Comments