Hello, friends today I am going to discuss the manufacturing process of steel in which you will learn different methods of making steel.

Steel is a multi-purpose alloy with many applications such as it is used in construction, automotive, aircraft industry, heavy industrial equipment, transportation infrastructure, home appliances, etc.

So without wasting time let's get started

What is Steel?

Steel is an alloy of iron and carbon in which the carbon content varies up to 1.5%.

Manufacturing Process of Steel

The following six methods are used in the process of manufacturing steel.

- Open Hearth Process

- Electric Process

- Crucible Process

- L.D. Process

- Bessemer Process

- Cementation Process

Open Hearth Process

An open hearth is a shallow hearth around which the roof and wall of refractory bricks are made.

Charging doors are mounted on the side of the walls.

The melting zone is connected to the generator by ports.

In this method, the pig iron and steel scraps are melted and refined at the hearth by the heat of the fuel burning.

The temperature inside the furnace is about 1500 °C.

During melting, some part of the carbon, mostly silicon and manganese, is removed by oxidation.

When the metal bath reaches the required amount of carbon, tapping is done with the furnace.

Using this method, mild steel and medium carbon steel are made by removing carbon from iron.

See in the figure the open hearth process arrangement.

|

| Open Hearth Process |

Electric Process

In this method, only electricity is used to generate heat.

The temperature can be easily controlled and regulated at all times.

Alloy steels like stainless steel, high-speed steel, etc are made using this method.

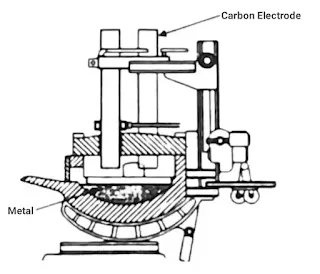

See in the figure the electric process arrangement.

|

| Electric Process |

Usually, the following two electric furnaces are used -

- Electric Arc Furnace

- High-Frequency Furnace

Electric Arc Furnace

In an electric arc furnace, the required heat is generated by striking an electric arc between carbon electrodes and a metal bath.

High-Frequency Furnace

In high-frequency furnaces, the required heat is generated by an inductor coil with an alternating current.

An alternating magnetic field is generated by the electric current generated in the steel. These currents are called eddy currents and due to their passing, the steel becomes hot.

Crucible Process

In this method, a mixture of wrought iron, steel scrap, and ferromagnes is melted with charcoal in an airtight crucible.

During melting the metal absorbs the required carbon from the charcoal and the steel is then filled into ingot molds.

Cast steel is usually made using this method.

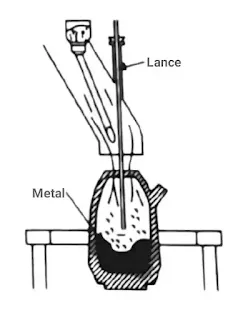

L.D. Process

L.D. Process is a Linz-donawitz process which is developed in Austria in 1949.

In this method, a basic oxygen converter is used to make high-quality steel in a relatively short time.

This method uses molten pig iron and steel scrap and oxygen is passed through a water-cooled lance for the oxidation of carbon and other impurities.

When the oxygen flow is complete, the foam is removed and the metal is collected in a ladle.

See in the figure Linz-donawitz process arrangement.

|

| Linz Donawitz Process |

Bessemer Process

In this method, steel is made by blasting compressed air from molten iron in which excess carbon and impurities are burnt in a large pear-shaped container.

Good quality steel is made using this method.

See in the figure Bessemer process during the manufacturing process of steel.

|

| Bessemer Process |

Cementation Process

In this method, carbon is added to the wrought iron. Wrought Iron Bars are packed in a box with charcoal powder and heated to approximately 900 °C to form blister steel. This blister steel is then cut into pieces, reheated and welded together, and then drawn into bars to form shear steel.

When this steel is reheated, the steel formed is called double shear steel.

So friends here you have to know the different manufacturing processes of steel with their diagram.

I hope you all enjoy this topic if you have any doubts then you can ask me through a comment or direct mail to me.

Thank You.

0 Comments