Hello friends, Today's topic is related to reaming operation.

In which you will learn all aspects related to reaming operation such as what is reaming operation, what is Reamers and their types as well as how to calculate reamer drill size?

Basically reaming operation is done by drilling machine, sometimes it is also done by lathe machine.

Nowadays, these machines are fully automated which work on cnc machining.

The main purpose of reaming operation is to create precise sizing and smooth finishing in an existing hole.

So without wasting time let's get started.

What is Reaming Operation?

Reaming is a cutting operation to make existing hole diameters more accurate and to improve surface finish.

The cutting tool used for reaming is known as a reamer.

What is Reamer?

A reamer is a multi-point cutting tool used to enlarge a previously opened hole while finishing it to a precise size.

Speed, feed, and reaming allowance can affect the precision of a rimmed hole.

The reaming speed is usually kept at about half the drilling speed.

Reaming can finish any hole to a precision of -0.005 mm or up to +0.005 mm.

Reamers are made from carbon tool steel or high-speed steel.

Carbide tip reamers are also found to which the carbide tips are joined by brazing at the cutting edges.

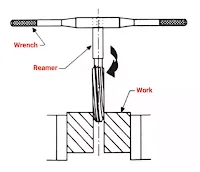

See in the figure that the reaming operation is performed with the help of reamers.

|

| Reaming Operation |

Types of Reamers

There are following two types of reamers are used.

- Hand Reamers

- Machine Reamers

Hand Reamers

Hand reamers have a square end that is used to remove metal up to 0.13 mm from the hole.

Machine Reamers

Machine reamers have a straight or taper end that is used under power.

Reaming By Hand

The following signs should be kept in mind while reaming by hand

- Clamp the job well in the vice.

- Check the reamer hole size which should be about 3% less than the size of the reamer.

- Place the reamer in the hole and check the vertical position.

- With light pressure, move the reamer clockwise.

- Use suitable coolant while reaming.

- Clean the reamer and job after reaming is complete and keep the reamer in its safe place.

Reaming by Machine

The following indications should be kept in mind while doing reaming by machine

- Clamp the job well on the table of the machine.

- Hold the reamer in place with the holder or adapter sleeve.

- Before starting, bring the reamer to the edge of the hole and feed it carefully.

- Use suitable coolant while reaming.

- Use the right speed. This is often less than the speed required for drilling so that the cutting edge does not overheat and deteriorate.

- Excessive feed should not be given.

- Clean the machine, reamer, and job after reaming is complete.

Precautions During Reaming Operation

- The reamer should be placed in a vertical position in the hole.

- The reamer should not be turned backward. Always use lard oil or any other suitable compound when reaming steel or wrought iron.

- Do not attempt to start the reamer on an uneven surface.

- From time to time, move the reamer upwards for reaming of the blind hole.

- Use a suitable reamer when reaming.

Formula for Calculating Reamer Drill Size

The following formula is used to calculate Reamer drill size.

R.D.S. = R.S. – (Under Size + Over Size)

Where,

R.D.S. = Reamer Drill Size

R.S. = Reamer Size

Undersize

The appropriate drill size is selected to obtain a reamer hole of a particular size.

It is called undersize.

This is an approved reduction in size as shown in the table below.

| Sr. No | Diameter of Reaming Hole | Under Size of Rough Bore Holes |

|---|---|---|

| 1 | Up to 5 mm | 0.1 mm to 0.2 mm |

| 2 | 5 mm to 20 mm | 0.2 mm to 0.3 mm |

| 3 | 21 mm to 50 mm | 0.3 mm to 0.5 mm |

| 4 | Above 50 mm | 0.5 mm to 1.0 mm |

0 Comments