Hello, friends today we are going to discuss the machinability index.

Before knowing the machinability index, first, we need to know what is machinability and how does it affect the machining process.

So without wasting time let's get started to know what is machinability index?

What is Machinability?

Chips can be cut from some materials in relative terms and from other materials with greater difficulty.

This difference can be attributed to the machinability of the respective materials.

Machinability is defined as the ease with which a metal is cut satisfactorily for the intended purpose.

So we can say that machinability is nothing but it is the property of a material by which it can be machined easily and quickly.

In general, good machinability is associated with the removal of material with moderate forces, minimal tool friction, and a good surface finish.

It is generally observed that high hardness gives poor machinability.

Factors Affecting Machinability

Machinability depends on the following factors :

- Chemical composition material of the workpiece such as alloying element.

- The microstructure of the workpiece material is like grain size.

- Mechanical properties of materials such as tensile strength, ductility, and hardness of workpiece material.

- The rigidity of the equipment and the work holding equipment.

- Cutting conditions such as cutting speed, feed, etc.

Evaluating of Machinability

In evaluating machinability, the following criteria should be considered:

- Rate of Metal Removal per Grinding Tool

- Tool Life between Grinding

- The magnitude of Cutting Forces

- Surface Finish Quality

- Generating Heat during Cutting

- Power Consumption during Cutting

Rate of Metal Removal per Grinding Tool

If the rate of metal removal is high then it can be said that the material has more machinability.

Tool Life between Grinding

The material which gives more life to the cutting tool is said to have more machinability than the material which gives less tool life.

The Magnitude of Cutting Forces

The lesser the cutting force required during machining of a material, the higher its machinability.

Surface Finish Quality

The better the surface finish on a material under given conditions, the better its machinability.

Generating Heat during Cutting

If the heat generated during machining of a material is less, then it is said to be machinable.

Power Consumption during Cutting

If less power is consumed then it is said to have high machinability.

Properties of High Machinability Metal

High machinability metals should have the following properties:

- A good surface finish can be produced.

- Higher cutting speeds can be used.

- The metal removal rate is high.

- Cutting tool wear is low.

- Low power consumption.

Machinability Index

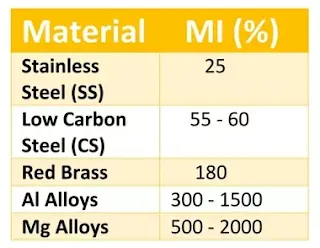

The machinability index of a material is a relative quantity.

The machinability index is used to compare the machinability of different metals.

Rated machinability of two or more metals may vary for the different cutting processes such as heavy turning, light turning, milling, etc.

The higher the machinability index of the metal, the greater the machinability of that metal.

See the machinability index of some materials in the figure.

|

| Machinability Index |

The formula of the Machinability Index

MI(%) = (Vi/Vs) × 100

Where,

MI=Machinability Index.

Vi = The cutting speed of the metal for 1-minute tool life.

Vs = The cutting speed of standard free cutting steel for 1-minute tool life.

So friends in this topic we have to know about machinability index as well as what is machinability and how to evaluate it.

I hope you like this post.

You can also follow us on Google News to read more such new posts.

Thank You.

1 Comments