Hello friends, Today we will cover all aspects related to unconventional machining process like their types, parts, working procedure, application, advantages, disadvantages, etc.

Unconventional machining processes are widely used where a lot of hard and brittle materials are found such as tungsten carbide, high speed steels, stainless steels, ceramics, etc. Which can not be processed by the conventional machining process.

Most of the conventional machining processes like lathe machines, planer machines, milling machines, drilling machines, slotting machines, shaper machines, etc. Already covered in the previous post.

Here we will

only know about the unconventional machining process.

So, without wasting time let's get started

What is Unconventional Machining Process?

An unconventional machining process is a very special type of machining process because in this process there is no direct contact between the tool and the workpiece.

In an unconventional machining process,

a form of energy (such as mechanical energy,

electrical energy, chemical energy,

etc.) is used to remove unwanted material from a

given workpiece.

For supporting the workpiece in these types of machining processes always fixtures are used.

It is also called a non-traditional machining process or non-conventional machining process.

So, If I continue to pronounce these names, then don't get confused.

Advantages of unconventional machining process

- It has good accuracy.

- It provides a good surface.

- Complex shapes can be made easily.

- It has longer tool life.

- The rate of metal removal is high.

Disadvantage of unconventional machining process

- The cost of this process is high.

- It requires skilled operators.

- Its setup is difficult.

Classification of Unconventional Machining Process

- Mechanical Energy Based

- Electrical Energy-Based

- Chemical and Electrochemical Energy Based

- Thermal Energy-Based

Mechanical Energy Based

Electrical Energy-Based

Chemical and Electrochemical Energy Based

Thermal Energy-Based

Types of Unconventional Machining Process

Some of the common types of unconventional machining processes are discussed which are used for machining using different energy sources:

- Abrasive Jet Machining

- Ultrasonic Machining

- Electrochemical Machining (ECM)

- Electrical Discharge Machining (EDM)

- Electron Beam Machining

- Laser Beam Machining

- Electrochemical Grinding

Abrasive Jet Machining

Abrasive jet machining is a mechanical energy based unconventional machining process mostly used in the machining of hard metals.

In

this machining, a concentrated stream

of abrasive particles like aluminum oxide, silicon carbide,

diamond powder, glass particles, etc is forced to strike a piece of the workpiece at high velocity.

These high velocity abrasive particles cut the metal into small pieces.

See in figure abrasive jet machining process and their working procedure described below in detail.

|

| Abrasive Jet Machining |

Working Procedure of Abrasive Jet Machining

- Firstly in abrasive jet machining air or gas like nitrogen, carbon dioxide, etc compressed in a gas compressor. Where the density and pressure of the gas increases.

- Now it sends the compressed gas to the filtration unit, from where the dust and other suspended particles are removed.

- Then It sends the clean gas to the dryer where its moisture is absorbed.

- Now, this clean and dry gas is sent to the mixing chamber where the abrasive particles are found in the abrasive feeder. (abrasive particles are about 10 to 50 micrometer bit size)

- Now, these high pressure (about 850 kPa) abrasive particles and gas are sent to the nozzle (the nozzle diameter ranges from about 0.18 to 0.80 mm), where its pressure energy is converted into kinetic energy.

- The velocity of the abrasive particles leaving the nozzle ranges from about 150 to 300 m/s.

- The distance between the workpiece and the nozzle (tungsten) is about 2 mm.

- Now, these high velocity abrasive particles are strikes on the workpiece. These high velocity abrasive particles remove the material through micro-cutting action as well as by brittle fractures of the work material.

Application of Abrasive Jet Machining

- It is used in the drilling and cutting of hard metals.

- It is used for machining brittle and heat sensitive materials like glass, mica, ceramic, sapphire, quartz, etc.

- It is used for manufacturing electronic components.

Advantages of Abrasive Jet Machining

- High surface finish.

- It can machine heat sensitive material.

- It is free from vibration.

- The initial cost is low compared to other non-traditional procedures.

- Thin sections can be made easily.

Disadvantages of Abrasive Jet Machining

- Low metal removal rate.

- Nozzle life is limited, so it needs to be replaced frequently.

- The abrasive particle cannot be reused in this process.

- This machine can not use for a soft and ductile material.

Ultrasonic Machining

Ultrasonic machining is also a mechanical energy based non-conventional machining process that is used to machine brittle and hard materials.

In ultrasonic machining, ultrasonic waves

are converted into mechanical vibrations, through the

magnetostrictive effect.

The ultrasonic machine generates a frequency of

20000 to 30000 Hz.

This process is used for cutting metal in many industries because of its low cost, no heat generated, and efficient machining.

See in the figure the ultrasonic machining process and their working procedure described below in detail.

|

| Ultrasonic Machining |

Working Procedure of Ultrasonic Machining

- First of all the low-frequency electric current is sent from the power supply (electric supply).

- This low frequency current is converted into high frequency current through some electrical equipment.

- This high frequency current passes through the transducer. The transducer converts this high frequency electric signal to high frequency mechanical vibration.

- This mechanical vibration passes through the booster.

- The booster amplifies this high-frequency vibration and sends it to the horn.

- Horn, also known as a tool holder, transferred this amplified vibration to the tool. Where the tool vibrates at an ultrasonic frequency.

- An abrasive gun is used to supply an abrasive slurry (eg, aluminum oxide, silicon carbide, boron carbide, diamond dust, etc.) and the mixture of abrasive slurry and water is sent between the tool and the workpiece.

- As the instrument vibrates, the abrasive slurry also starts vibrating at this high frequency.

- This abrasive slurry attacks the workpiece and gives it a metallic appearance.

Application of Ultrasonic Machining

- It is used to produce fine holes.

- It is the best suited machine for hard and brittle materials.

- With the help of this, a cavity or hole is easily made in the dies.

Advantages of Ultrasonic Machining

- The workpiece is free from any stress after machining.

- Extremely hard and brittle materials can be easily removed.

- Excellent accuracy and surface finishing are achieved.

- Operational cost is very low.

- This process is environmentally friendly as it takes place without any chemical reactions and heating.

- It is suitable for both conducting and non-conducting materials.

Disadvantages of Ultrasonic Machining

- In this, the metal removal rate is low and can not be used for large machining operations.

- The initial cost and initial cost of the equipment are very high.

- The power consumption is quite high.

- The slurry may need to be changed frequently.

- Equipment life is short.

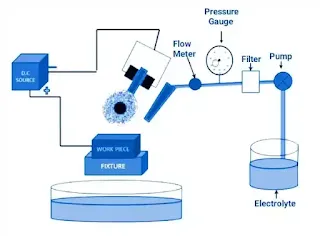

Electrochemical Machining (ECM)

Electrochemical machining

is an electro-chemical based non-conventional machining process in which metals

are removed by electrochemical dissolution. This process is the opposite

of the electroplating process.

Electrochemical

machining works on Faraday's law of electrolysis.

The tool is

connected with the negative terminal (as the cathode) of the battery,

and the workpiece is connected with the positive terminal (as the

anode) of the battery.

Both are

kept at a distance in an electrolyte solution.

When DC current (3 to 30V) is supplied to the electrode, the metal begins to move away from the workpiece.

See in figure electrochemical machining process and their working procedure described below in detail.

|

| Electrochemical Machining |

Working Procedure of Electrochemical Machining

- In ECM, NaCI is usually in water as an electrolyte.

- The tool is connected to the negative terminal, and the workpiece is connected to the positive terminal.

- When current passes through the electrodes, the anode or workpiece and the cathode or tool reaction occurred >

- NaCI = (Na+) + (CI-)

- H20 =( H +) + ( OH-)

- Positive ions move towards the tool and negative ions towards the workpiece.

- Thus the hydrogen ion moves towards the tool.

- As hydrogen reaches the tool, it takes some electrons from it and turns into a gas. This gas goes into the environment.

Application of Electrochemical Machining

- ECM is used in the machining of disc or turbine rotor blades.

- It can be used to slot very thin walled collets.

- The ECM is used to generate the internal profile of the internal cam.

- ECM is also used in the Production of satellite rings and connecting rods, machining of gears and long profiles, etc.

Advantages of Electrochemical Machining

- It can machine very complex surfaces.

- A single tool can be used for machining a large number of workpieces.

- Metal machining does not depend on the strength of the tool and the hardness of the tool.

- ECM provides a very high surface area.

Disadvantages of Electrochemical Machining

- High initial cost of the machine.

- The design and tooling system is complex.

- The fatigue property of the machined surface may be reduced.

- Nonconducive materials cannot be machined.

- Blind holes cannot be machined through ECM.

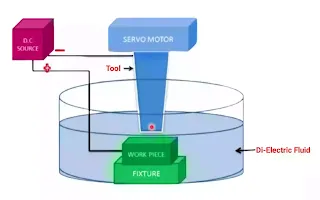

Electrical Discharge Machining (EDM)

This machining process uses

an electric spark to cut the metal.

The spark generated by this process produces heat, which removes the metal by erosion and evaporation.

This process takes

place in dielectric fluid. In this non-traditional machining process,

both the workpiece and the tool are made of conductive material.

See in figure the electrical discharge machining process and their working procedure described below in detail.

|

| Electrical Discharge Machining |

Working Procedure of Electrical Discharge Machining

- First of all, both the workpiece and the tool are immersed in dielectric fluid. This dielectric fluid helps to control the arc discharge.

- There is a very small gap (about 0.5 mm) between the workpiece and the tool.

- A high-frequency current is sent to the electrode, which creates a spark between the tool and the workpiece.

- Due to erosion and evaporating ions, the metal starts coming out of the workpiece.

- Chips and suspended particles are removed from between the workpiece and the tool so that it does not cause a short circuit. All this is possible by a continuous supply of dielectric fluid.

Application of Electrical Discharge Machining

- It is specially used for master die makers.

- Finished products

- Long aspect hole

Advantages of Electrical Discharge Machining

- Every conductive material can be cut by this process.

- A complex dies sections and complex shapes can be produced with precision.

- This process is independent of burrs.

- Thin sections can be easily formed without deforming any parts.

- Pieces of hard workpieces can be easily cut.

Disadvantages of Electrical Discharge Machining

- In this machining process, the equipment wears out more.

- Good electrical conductors can only be made by EDM.

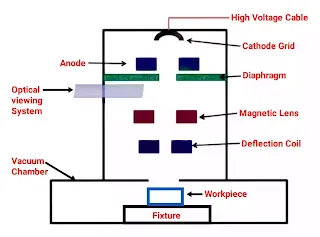

Electron Beam Machining

It is a thermo- electric energy based non-traditional machining process that does

not use tools.

This machining process works on the basic principle of converting the kinetic energy of electrons into heat energy.

When a high-speed electron strikes a piece of a workpiece, they convert their kinetic energy into heat energy.

This heat energy evaporates

the material on the surface of the workpiece.

This process is done in a vacuum otherwise the electron collides with the air particle and loses its energy before hitting the material. It is mostly used for drilling holes in any shape.

See in figure electron beam machining process and their working procedure described below in detail.

|

| Electron Beam Machining |

Working Procedure of Electron Beam Machining

- Firstly the electron gun produces electron particles with high velocity.

- These electron particles move towards the anode. The anode is placed after the cathode tube.

- Now it highly intense electron beam passes through magnetic lenses. There is a chain of lenses that only takes care of the converging electron that passes through it. It absorbs all divergent electrons and low energy electrons. It provides a high-quality electron beam.

- This electron beam now passes through the electromagnetic lens and deflecting coil which focuses the electron beam at one spot.

- A highly intense electron beam strikes the piece of the workpiece where the kinetic energy of the electrons is converted into thermal energy.

- Due to this high temperature generated by the conversion of kinetic energy into heat energy, the substance melts and vaporizes, due to which the material begins to be removed (cut).

- This whole process takes place in a vacuum chamber otherwise these electrons collide with the air particle between the path and lose their kinetic energy.

Application of Electron Beam Machining

- It is used to produce holes of very small sizes from 100 micrometers to 2 millimeters.

- It is used for making holes in diesel injection nozzles.

- Used in the aerospace industries for the production of turbine blades for supersonic engines and in nuclear reactors.

Advantages of Electron Beam Machining

- It can be used to produce the very small size of holes in any shape.

- It can machine any material irrespective of its hardness and other mechanical properties.

- It provides a good surface.

- Highly reactive materials can be easily machined because machining is done under a vacuum.

Disadvantages of Electron Beam Machining

- Capital cost is high.

- Require high skill operator.

- The rate of material removal is low.

- Require regular maintenance.

- Producing the perfect vacuum is difficult.

Laser Beam Machining

Laser beam machining is an also thermo-electric energy based non-traditional machining process, which uses a laser beam to heat a material.

In this machining process, the metal is removed from the surface of the workpiece by melting and evaporating the metal particles.

It is a

non-traditional machining process in which

no tools are used.

It is used for machining both metallic and non-metallic materials.

It is mostly used for cutting materials and drilling holes.

See in figure laser beam machining process and their working procedure described below in detail.

|

| Laser Beam Machining |

Working Procedure of Laser Beam Machining

- First, the laser material (CO2) or other gases are filled into the laser vacuum (discharge) tube.

- Now let's turn on the power switch, which is connected by the flash lamp. This lamp produces light energy, which is used to excite the electrons of the atom.

- The atoms of the laser substance absorb energy from the light energy produced by the flash lamp and it converts the lower energy level of the atomic orbital electron to the higher energy level. This is the unstable state of the atom.

- This energy is initially completely immersed in the material of the laser. After the atom has absorbed enough energy, it starts emitting energy continuously.

- This laser light is collected by the focusing lens which is directed towards the workpiece.

- The laser now sent to the workpiece begins to melt or vaporize the surface of the workpiece, and the machining process begins.

Application of Laser Beam Machining

- It is used to drill small holes of diameter approximately 0.005 mm in refractory and ceramic materials.

- It is used for drilling holes and cutting both metals and non-metals.

- It is mostly used in aerospace industries.

- Used for complex profiles where machining by the tool is not possible.

Advantages of Laser Beam Machining

- It can drill and cut all materials.

- High surfaces are obtained in this machining process.

- The tool is not used in this machining process.

- Micro holes can be drilled accurately.

- Very hard materials can be cut through laser beam machining.

- High accuracy can be achieved.

Disadvantages of Laser Beam Machining

- High capital and maintenance cost.

- It cannot be used to make blind holes.

- Lasers may lead to a safety hazard.

Electrochemical Grinding

|

| Electrochemical Grinding |

Working Procedure of Electrochemical Grinding

- The grinding wheel is attached to the spindle which is made of diamond particles.

- The spindle is used to rotate the grinding wheel. The grinding wheel rotates at a speed of 900 to 1800 rpm/min.

- The workpiece is connected to the positive terminal and the tool is connected to the negative terminal.

- A gap of 2.5 mm is maintained during the process. The electrolyte flows between this gap.

- Sodium chloride and sodium nitrate are used as electrolytes.

- The electrolyte also acts as a coolant. It is filtered and circulated again.

- When power is supplied, ions are removed from the workpiece.

- The positive ions move towards the grinding wheel and negative charges are carried away by electrolytes.

- Some amount of metal is removed by the grinding process.

Application of Electrochemical Grinding

- Used to machine hard and brittle materials.

- Suitable for grinding tungsten carbide tools.

- Used to machine thin components.

Advantages of Electrochemical Grinding

- Fast process and high metal removal rate.

- Very hard materials are removed.

Disadvantages of Electrochemical Grinding

- Only suitable for conducting material.

- Requires high electrical power.

- High investment.

- Not suitable for complex shapes.

- Electrolytes can cause corrosion.

I hope that I have cleared all your doubts related to the unconventional machining process.

If you have any doubts related to this topic then you can ask me through contact us page or directly mail to me.

Thank You

5 Comments

Thank you